The Importance of Granulation in Organic Fertilizer Production Lines: Techniques, Equipment, and Benefits

Introduction The production of organic fertilizers involves several stages, from raw material collection to final…

Introduction The production of organic fertilizers involves several stages, from raw material collection to final product distribution. One of the most important processes in an organic fertilizer production line is granulation. Granulation is the process of forming granular particles from powdered organic materials, which is crucial for enhancing the usability, storage, and application of the…

1. Introduction Organic fertilizer pelletizers are crucial equipment in the production of organic fertilizers. Their stable and efficient operation is essential for ensuring the continuous production of high – quality organic fertilizer granules. Regular and proper maintenance is the key to extending the service life of organic fertilizer pelletizers, reducing equipment failures, and maintaining high…

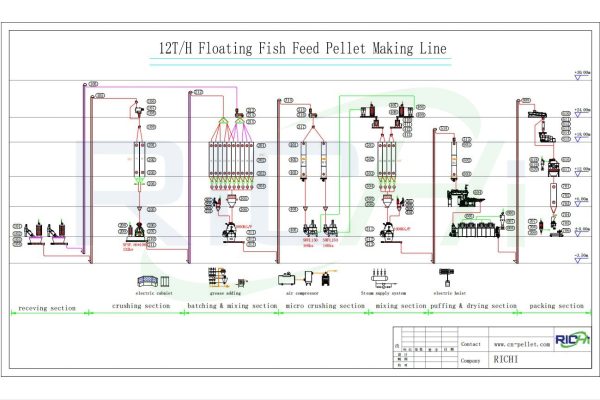

The production of fish feed pellets is a critical aspect of aquaculture, providing fish with the necessary nutrition for growth, health, and overall productivity. Fish feed pellet machines are designed to efficiently convert raw materials into pellets that meet the dietary needs of various fish species. The processing procedures involved in using a fish feed…

In the rapidly expanding field of aquaculture, the quality and consistency of fish feed are critical factors that directly influence the growth, health, and overall productivity of aquatic species. As global demand for fish and seafood continues to rise, the need for efficient, reliable, and high-performance fish food manufacturing technologies has become more pressing than…

Mesh belt dryers are widely used in various industries for drying materials such as food, chemicals, and biomass. The efficiency and effectiveness of these dryers largely depend on the quality of their accessories. High-quality components not only enhance the performance of the dryer but also significantly impact production costs. This article explores the key accessories…

Mesh belt dryers are essential for efficiently drying various materials, including food products, chemicals, and biomass. The effectiveness of these dryers largely depends on the quality of their accessories, which include components such as the mesh belt, heating system, fan system, control system, and cooling system. Verifying the quality of these accessories during actual production…

Belt dryers are widely used in various industries for drying materials such as food, chemicals, and biomass. The electrical control system is a critical component of a belt dryer, as it regulates the operation of the machine, ensuring optimal performance and efficiency. Regular checks of the electrical control system are essential to prevent malfunctions, improve…

Belt dryers are essential industrial equipment used for drying a wide range of materials, including food products, chemicals, and biomass. One of the critical aspects of a belt dryer’s operation is its air system, which plays a vital role in ensuring efficient and uniform drying. This article explores the various air system components of a…

Belt dryers are widely used in various industries for drying materials such as food, chemicals, and biomass. The vacuum system is a critical component of a belt dryer, as it creates the necessary low-pressure environment for efficient drying. Ensuring the proper functioning of the vacuum system is essential for maintaining optimal performance, product quality, and…

Belt dryers are essential equipment used in various industries for drying materials such as food, chemicals, and biomass. Ensuring that a belt dryer operates efficiently and effectively is crucial for maintaining product quality and optimizing production processes. One of the best ways to verify the performance of a belt dryer is through functional testing. This…